R&D Center

R&D Center

About R&D Center

About R&D Center

The Guanghua Chuangshi Dezhou Factory has a standard ice storage laboratory and a corrosion resistance laboratory, each batch of different types of ice-storage products have been through the ice-storage, ice-melting process of the actual operation and performance testing, flow resistance detection (pressure drop detection) , corrosion resistance testing.

About the R&D team

About the R&D team

Brief introduction to the core group:

Zheng Qing: Graduated from Beijing University of Technology with a master's degree (thermal engineering) in 1996, and began to work on the promotion and practice of ice storage; Worked in many professional ice storage companies such as FAFCO, CIAT and Gaoling Energy. Now working in GHCS Company, he has detailed and in-depth practical experience in various types of ice storage equipment and ice storage systems, such as plastic coils and steel coils.He is one of the earliest professional practitioners of ice storage in China.

Dong Xingjie: Doctor of Refrigeration and Cryogenic Engineering, Shanghai Jiaotong University. He has been engaged in ice storage technology research for 26 years, published more than 10 related papers, won nearly 30 patents, and won provincial and ministerial science and technology progress awards for many research achievements. He was awarded the title of "Advanced Scientific and Technological researcher" at the municipal level and was selected as outstanding young and middle-aged talents at the provincial and municipal levels respectively. Since 1996, he has entered the ice storage industry, participated in or presided over more than 100 ice storage air-conditioning projects, including the Shanghai Science and Technology Museum (the venue of APEC Conference, responsible for optimizing control), Shanghai World Expo Center (ice storage and water source heat pump, responsible for ice storage device design), Guangzhou University Town (the world's largest ice storage project, responsible for optimizing control) Hangzhou East Railway Station (the largest railway station in Asia in parallel with Shanghai Hongqiao, which uses ice storage and ground source heat pump technology, is responsible for system design, automatic control and ice storage equipment, and the single ice storage equipment has the largest capacity in the world), Beijing Daxing International Airport (responsible for the design and installation of ice storage equipment, it is the largest project in the world which useinternal melting icethermal storage technology), Zhuhai Hengqin 1 #, 2 #, 3 # 5 # energy station (responsible for the design of external ice melting coil and control system) and other large well-known projects.

Advanced laboratory

Advanced laboratory

The R&D center has ice storage laboratory and salt spray laboratory. The main research fields are solid-liquid phase change heat transfer, gas-liquid two-phase flow heat transfer and flow, air conditioning load prediction, optimal control of ice storage air conditioning, corrosion resistance of metal materials, etc.

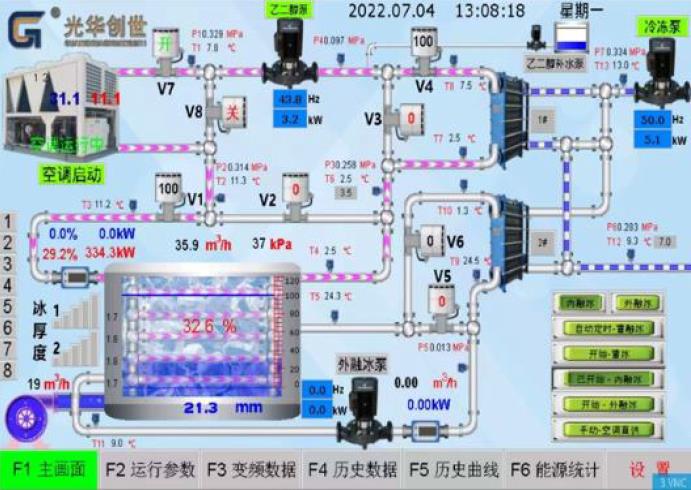

(1)Ice storage laboratory

The ice storage laboratory can realize the research on the ice making, ice melting and resistance performance of internal melting coil, external melting coil and direct evaporative coil. Through the combination of theoretical simulation and experiment, more reasonable coil pipe diameter, optimal coil flow and arrangement spacing are selected according to the specific conditions of different projects, so that the ice making, ice melting and resistance performance of the ice storage coil can be comprehensively optimized.

Before the delivery of each project, the R&D Center conducts tests in the laboratory, invites customers to inspect various performance data in the laboratory, and also authorizes customers to remotely monitor the whole process. The R&D Center provides complete experimental reports.

(2)Corrosion resistance laboratory

The salt spray laboratory mainly studies the corrosion resistance of metal materials. GHCS ice storage coil is made of SUS304 stainless steel (Zhangjiagang Posco, etc.). It is subject to strict passivation treatment to form a dense passivation film with excellent anti-corrosion performance before leaving factory. It avoids various corrosion conditions caused by various free metals, welding heat affected areas, and surface effects of various processing links. After sufficient passivation, no processing procedure is allowed.

GHCS Factory has an independent pickling and passivation workshop. Each batch of ice coils is subject to pickling and passivation treatment before leaving the factory to improve the corrosion resistance of ice storage coils and extend their service life. The salt spray laboratory conducts spot check on each batch of pickling and passivation samples and issues inspection reports.